/

Swiss Robotics Startup Mimic Raises $16M to Bring Human-Level Dexterity to Factory Floors

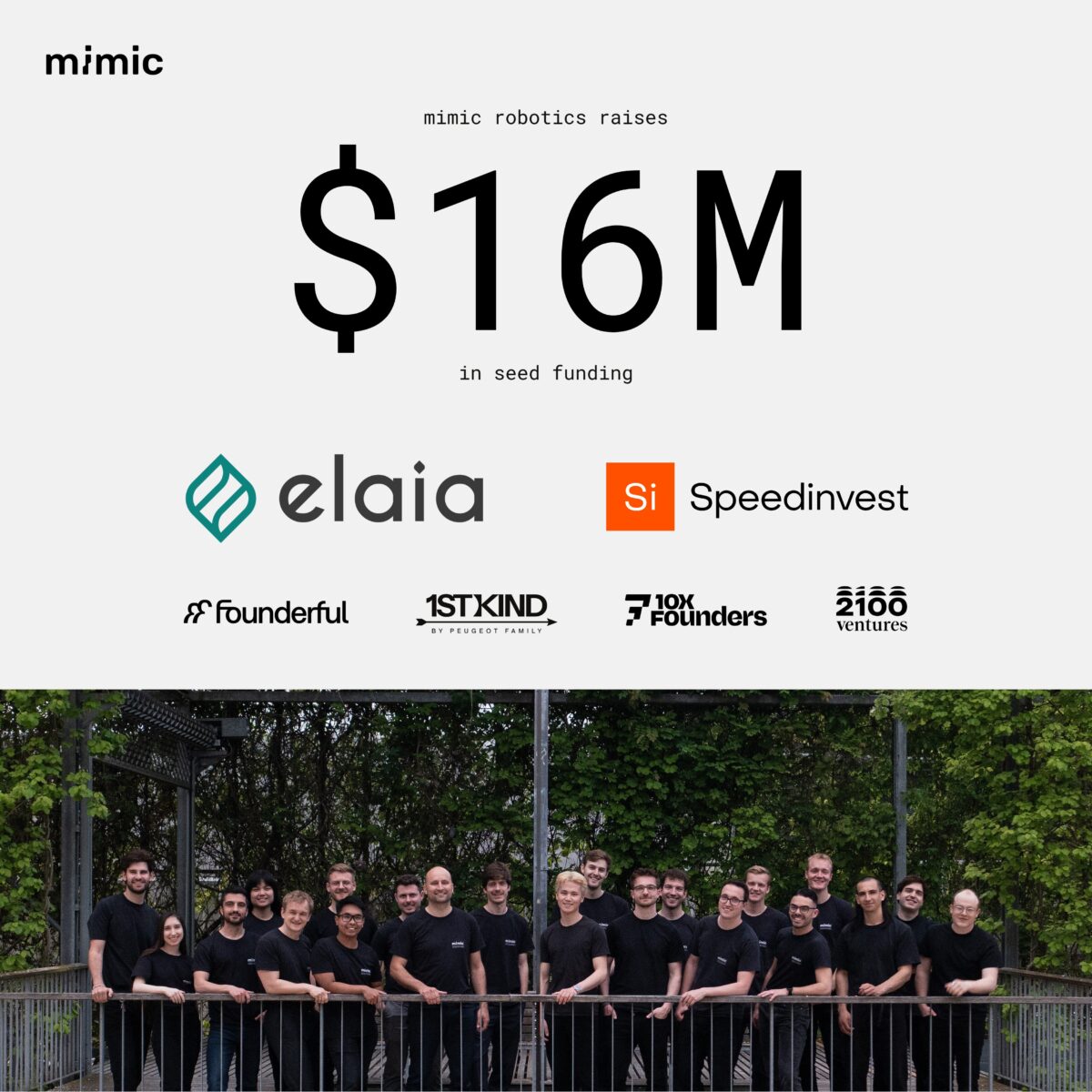

Billions flow into humanoid robotics in the US and China, but a Zurich-based team has built something different: robots that don’t need a full body to match human skill. Mimic’s $16 million seed round, led by Paris-based Elaia alongside Speedinvest, brings the company’s total funding to over $20 million and positions Switzerland as a serious contender in the global race toward general-purpose robotics. The heavily oversubscribed round will fund deployments with Fortune 500 manufacturers and global automotive brands already piloting the technology. Identified in the Swiss Deep Tech Report 2025 as a rising star in Physical AI, Mimic is delivering on its potential.

The Automation Gap That Traditional Robots Cannot Close

On factory floors worldwide, millions of intricate manual tasks still depend on human hands. These tasks span manufacturing, assembly, and logistics, where objects vary in position, materials change texture, and disturbances require real-time correction. Traditional industrial robots excel at repetitive, pre-programmed motions in controlled environments, but they struggle when conditions deviate from script.

The challenge extends beyond technical limitations. Vacancy rates for factory floor positions range from 40 to 70 percent in these sectors as aging workforces shrink and production costs rise. Industries face mounting pressure to reshore production amid global uncertainty, yet the labor to support local manufacturing proves increasingly difficult to find.

“This funding will accelerate the deployment of frontier Physical AI to automate the millions of intricate manual tasks across manufacturing, assembly, and logistics that still depend on human skill,” says Stefan Weirich, mimic’s co-founder and CEO in an interview with Deep Tech Nation Switzerland.

The solution that has captured billions in investment, full-body humanoid robots, faces its own obstacles. Safety concerns, regulatory hurdles, high costs, and limited dexterity have slowed real-world deployment despite the appeal of the form factor.

A Different Path: Dexterous Hands, Not Full Bodies

Humanoids are exciting, but there aren’t many industrial scenarios where the full-body form factor truly adds value

– Stephan-Daniel Gravert, co-founder and CPO, mimic

Mimic’s approach pairs AI-driven robotic hands with proven, off-the-shelf robot arms. The logic is straightforward: most industrial tasks require human-level dexterity in the hands, not bipedal locomotion.

“Humanoids are exciting, but there aren’t many industrial scenarios where the full-body form factor truly adds value,” says Stephan-Daniel Gravert, mimic’s co-founder and CPO. “Our approach pairs AI-driven dexterous robotic hands with proven, off-the-shelf robot arms to deliver the same capabilities in a way that is much simpler, more reliable and rapidly deployable.”

The technical innovation lies in how mimic trains its physical AI models. Skilled operators wear proprietary data collection devices while performing their regular work on factory floors. This captures detailed movement data from live production settings without disrupting operations. The demonstrations train AI models via imitation learning, enabling mimic’s robotic hands to reproduce human technique and adapt autonomously.

Learning From Humans, Not Just Code

Traditional robotic solutions focus on narrow use cases, requiring expensive custom engineering for each application. A robot designed for automotive assembly needs reprogramming whenever the production line changes. Mimic’s foundation AI model aims to understand common sense and the physical world, executing tasks with minimal demonstration rather than requiring skilled technicians to reprogram for every variation.

“Our general purpose AI models allow us to automate manual labour in a way that simply was not possible before,” says Elvis Nava, co-founder and CTO at mimic. “Thanks to our unique focus on human-like dexterity and human data, we are competitive at the robot foundation model layer as well as the application layer.”

The company’s physical AI models enable robots to react autonomously to changing positions and orientations of objects, handle disturbances, and self-correct their actions in environments designed for humans.

What International Investors Saw in Switzerland

They were drawn to Switzerland’s reputation for reliability and quality, which are essential in robotics, and to the exceptional talent coming out of the Swiss robotics ecosystem and ETH Zurich

– Stefan Weirich, co-founder and CEO, mimic

For Elaia and Speedinvest, mimic represents more than a promising technology. According to Weirich, the investors pointed to Switzerland’s reputation for reliability and quality, attributes that matter deeply in industrial robotics where downtime carries significant costs.

“They were drawn to Switzerland’s reputation for reliability and quality, which are essential in robotics, and to the exceptional talent coming out of the Swiss robotics ecosystem and ETH Zurich,” Weirich says. “For them, mimic represents Swiss engineering and innovation applied to one of the most ambitious challenges in technology today: bringing frontier AI research into production by capturing human-level skill and intelligence in robotics.”

The funding also reflects growing recognition that Europe can compete in general-purpose robotics, a field increasingly dominated by US and Chinese players. Clément Vanden Driessche, Partner at Elaia, emphasizes the technical breakthrough: “The world-class team at mimic is addressing one of the most challenging problems in physical AI: dexterous manipulation. mimic’s breakthrough approach integrates a proprietary robotic hand, state-of-the-art foundation models for robotics, and novel data acquisition and training methods.”

Andreas Schwarzenbrunner, General Partner at Speedinvest, frames the investment in broader terms: “At Speedinvest, we’ve always believed that Europe’s strength lies in marrying world-class engineering with foundational research. With mimic, we see exactly that: a platform that unlocks human-level dexterity with frontier AI and solves billion-dollar problems on factory floors today. This is the moment Europe steps forward to compete and lead in the new era of AI and robotics.”

The Swiss Ecosystem Advantage: From Lab to Market

Mimic spun out of ETH Zurich in 2024, bringing together a multidisciplinary team of 25 engineers, researchers, and operators expected to grow past 30 by year end. The ETH foundation provided cutting-edge research and access to exceptional talent, but the broader Swiss innovation ecosystem proved equally important.

“ETH gave us the foundation in cutting-edge research and access to an exceptional talent pool, but just as important was the broader Swiss innovation ecosystem around it,” Weirich says. Programs including Talent Kick, Venture Kick, and Innosuisse provided resources, coaching, and sparring partners who helped translate deep-tech research into a scalable business.

The support extended beyond funding. Organizations like the ETH AI Center and ESA BIC offered structure for refining business models, perfecting pitches, and navigating early partnerships with industrial pilots.

“From refining our business model and pitch to navigating early partnerships and industrial pilots, that network gave us both the structure and the confidence to move from the lab to real-world deployments,” Weirich explains. “Support from Swiss innovation grants also provided the early runway to focus on technology and product quality before scaling commercially.”

This ecosystem approach appears to be working. Over the past year, mimic secured non-dilutive funding from Switzerland’s federal innovation agency and was selected for the AWS Generative AI Accelerator, a program supporting early-stage companies applying advanced AI to real-world challenges.

Mimic’s success reflects a broader momentum in Swiss physical AI and robotics. Switzerland hosts a concentration of companies working at the intersection of AI and physical systems, with robotics and hardware startups setting investment records in 2024, reaching approximately $250 million across more than 30 financing rounds. From autonomous systems to advanced manufacturing, Swiss research institutions and startups are translating academic excellence into commercial applications. The combination of world-class universities like ETH Zurich and EPFL, which rank among Europe’s top engines for deep tech spinoffs, supportive funding mechanisms, and a culture that values precision engineering creates conditions where deep-tech companies can develop technology thoroughly before scaling. As global competition in physical AI intensifies, Switzerland’s approach of building on strong fundamentals rather than chasing rapid deployment may prove to be a strategic advantage.

Commercial Strategy: Scaling Production-Ready Systems

The new capital will accelerate development of mimic’s foundation AI model and humanoid robotic hands, but the primary objective extends beyond R&D. According to Weirich, the focus is on scaling industrial deployments with global manufacturers and logistics providers.

“Beyond advancing our AI models and robotic hands, the focus is on scaling industrial deployments with global manufacturers and logistics providers by developing repeatable, production-ready systems and building the foundation for international expansion,” he says.

Mimic’s technology is already being piloted with top-tier manufacturers, including Fortune 500 companies and global automotive brands. The company is also partnering with leading multinational logistics providers and seeing strong customer demand across labor-intensive sectors.

The market opportunity is substantial. Analysts project the global humanoid and dexterous robotics market alone could reach $38 billion by 2035, within a broader robotics market estimated between $200 billion and $1 trillion by 2040.

Five Years Out: Robots as Collaborative Colleagues

Mimic’s vision for the next five years centers on fundamentally changing how manual labor functions in manufacturing and logistics. The goal is not full automation but rather robots that work seamlessly alongside people.

“In five years, robots powered by mimic’s physical AI will work seamlessly alongside people on factory floors, taking on the complex, variable, and dexterous tasks that have so far remained impossible to automate,” Weirich says. With vacancy rates reaching 40 to 70 percent as industries face aging workforces and talent shortages, the technology addresses a critical bottleneck.

The next generation of robots will combine human-like dexterity with the intelligence and adaptability to understand their environment and interact naturally with people. This removes a major constraint in production and allows humans to focus on work that is more meaningful, creative, and higher value, both for them and for the industry.

“We’re at an inflection point in robotics where learning-based systems meet real industrial needs,” Weirich says. “We make dexterity deployable at scale, closing the gap between what AI can do in the lab and what factories actually need. Europe has the talent, the infrastructure, and the demand, and we’re building the company that brings all of this together.”

FAQ on mimic

1. What is Mimic and what makes their approach to robotics unique?

Mimic is a Zurich-based robotics company that has developed AI-driven dexterous robotic hands that pair with standard robot arms, rather than building full humanoid robots. Their approach focuses on replicating human-level dexterity where it matters most in the hands making their solution simpler, more reliable, and rapidly deployable compared to full-body humanoids.

2. How much funding has Mimic raised and who are their investors?

Mimic recently closed a $16 million seed round led by Paris-based Elaia alongside Speedinvest, bringing their total funding to over $20 million. Swiss investor Founderful, which led Mimic’s earlier $2.5 million pre-seed round in 2024, also participated in the seed round alongside 1st Kind, 10X Founders, 2100 Ventures, and Sequoia Scout Fund. The round was heavily oversubscribed and will fund deployments with Fortune 500 manufacturers and global automotive brands.

3. How does Mimic’s technology learn to perform tasks?

Mimic uses a proprietary imitation learning approach. Skilled factory workers wear data collection devices while performing their regular work, capturing detailed movement data from live production settings. This data trains AI models that enable Mimic’s robotic hands to reproduce human technique and adapt autonomously to changing conditions.

4. What problem is Mimic solving in manufacturing?

Millions of intricate manual tasks in manufacturing, assembly, and logistics still depend on human hands because traditional robots struggle with variable conditions. Meanwhile, factory floor vacancy rates range from 40-70% due to aging workforces and labor shortages. Mimic’s robots can handle these complex, variable tasks while addressing the critical labor gap.

5. Who is already using Mimic’s technology?

Mimic’s technology is being piloted with Fortune 500 manufacturers, global automotive brands, and leading multinational logistics providers across labor-intensive sectors. The company is scaling production-ready systems for these industrial deployments.

6. How did Switzerland’s ecosystem contribute to Mimic’s success?

Mimic spun out of ETH Zurich in 2024, leveraging the university’s cutting-edge research and exceptional talent pool. The broader Swiss ecosystem provided crucial support through programs like Talent Kick, Venture Kick, Innosuisse, the ETH AI Center, and ESA BIC. Switzerland’s federal innovation agency also provided non-dilutive funding, giving Mimic the runway to focus on technology quality before scaling commercially.

7. What is the market opportunity for dexterous robotics?

Analysts project the global humanoid and dexterous robotics market could reach $38 billion by 2035, within a broader robotics market estimated between $200 billion and $1 trillion by 2040. This represents substantial growth potential for companies solving real industrial automation challenges.

8. What is Mimic’s vision for the next five years?

In five years, Mimic envisions robots powered by their physical AI working seamlessly alongside people on factory floors, handling complex, variable, and dexterous tasks previously impossible to automate. The goal is collaborative robotics that allows humans to focus on more meaningful, creative, and higher-value work.

9. How strong is Switzerland’s robotics ecosystem?

Switzerland hosts a strong concentration of companies working at the intersection of AI and physical systems. In 2024, robotics and hardware startups set investment records, reaching approximately $250 million across more than 30 financing rounds. World-class institutions like ETH Zurich and EPFL rank among Europe’s top engines for deep tech spinoffs.

10. Why did international investors choose a Swiss robotics company?

Investors were drawn to Switzerland’s reputation for reliability and quality (essential in industrial robotics where downtime is costly) and the exceptional talent from the Swiss robotics ecosystem and ETH Zurich. They saw Mimic as representing Swiss engineering and innovation applied to one of technology’s most ambitious challenges: bringing frontier AI into production.

More Content

-

Today marks a defining moment for the Swiss innovation ecosystem. Deep Tech Nation Switzerland officially launching Project Switzerland, a national initiative with a singular, critical…

-

More money has flowed into all Swiss scale-ups per capita than into scale-ups in the US or Israel. This is backed by a ten-year growth…

-

Impatience is Imperative There is a distinct cultural friction when a Swiss founder steps into the US market. In Switzerland, the prevailing operating system is…